With the new P1S, I can print using the higher temperature filaments like ABS. I’m very excited by this idea, as I see a lot of value in a plastic more resistant to water and heat.

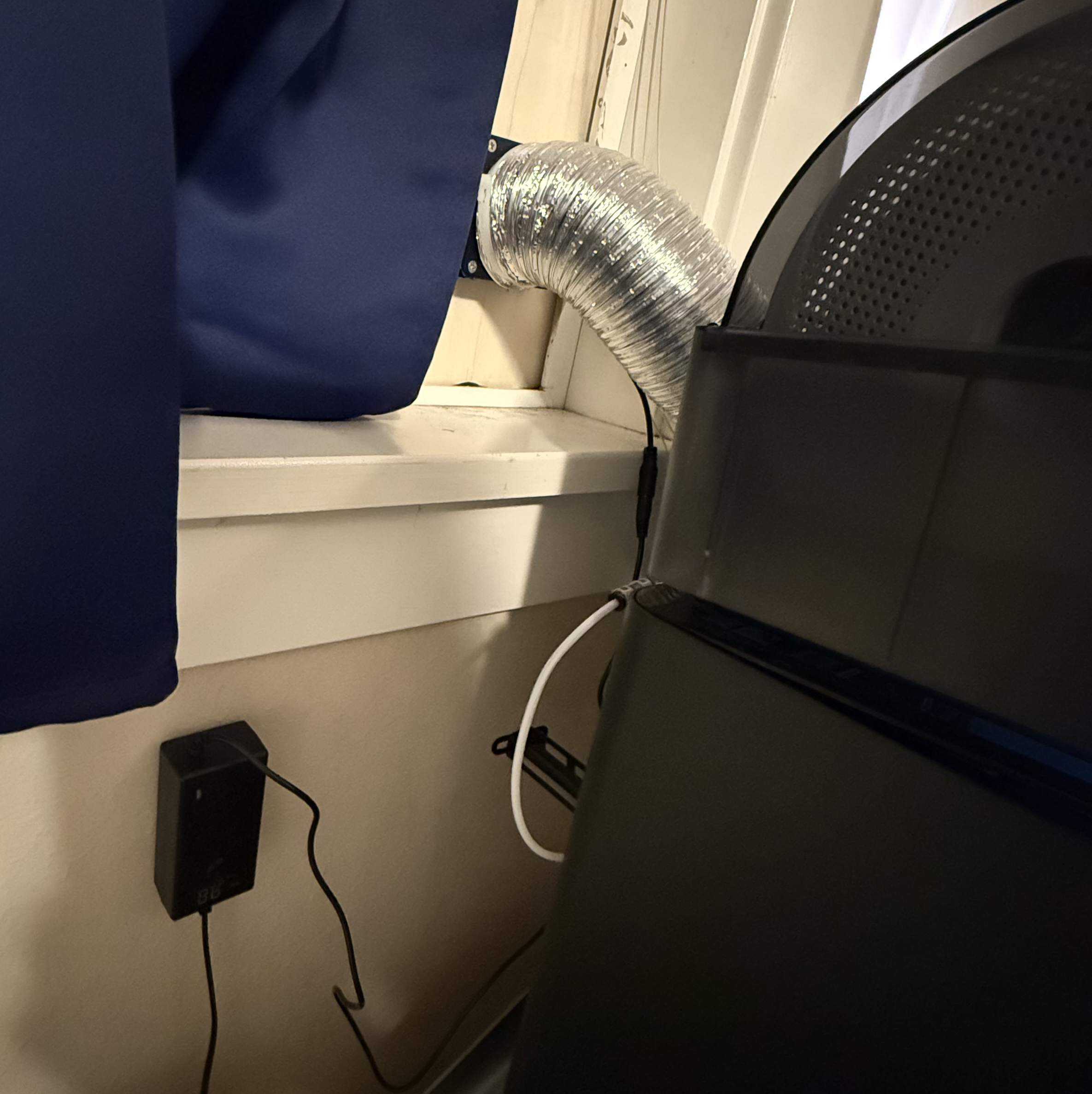

Of course, with ABS comes smell and harmful gases. I needed a way to vent this guck without having to move the printer to my garage (where it would never be seen again!) or something. I finally came up with a plan that required me to rearrange the office, but when it was all done was it ever worth it!

First, as I said, I had to rearrange somewhat. In this case, it meant moving the P1S closer to the window. That meant moving a bunch of other furniture, but it came out nice – in some ways an improvement. I had also found this bizarre work shelf thing at St. Vinnie’s, much more solid than the table I was using with a lot of storage and access to tools and such. That really helped as well.

To set this ventilation system up I used a 3D print and a bunch of general hardware, mostly from Home Depot.

- 3D Print – Low Profile Exhaust Vent by mcmaven

- 3″ x 8 ft. Semi-rigid Aluminum Duct

- 3″ Axial exhaust fan, variable speed

- Lasco Rubber Sheet – 1/8″ x 12″ x 12″ (for ‘sealing’ the area around the fan above)

- 7″ x 36″ x 3/4″ solid wood board

- Misc. bolts, screws, nuts, washers, velcro, etc.

So I printed the exhaust vent and scooped up the other parts needed. I carefully marked out a hole through the board to allow the fan to be bolted to it, with a rubber sheet piece on each side to seal it up as much as possible. With the fan above, I put the square mesh vent plate on the outside facing side of the board, with the fan and such inside. Then it was just a matter of trimming and adjusting until everything fit together and air flowed through the system. Note that I did remove the charcoal filter inside the P1S, on the theory that it would impede air flow with what I was doing.

It worked! I can’t smell the ABS (but I can if I take a whiff through the new fan from the outside). It looks decent, or at least well hidden, behind the printer. I don’t expect much in the way of problems, but it would be easy to fix if needed.

I velcro’d the controller for the fan to the wall, so it was reachable without flopping around.